What Is a Volumetric Mixer? Your Essential Guide to On-Site Concrete Mixing

Discover the transformative potential of volumetric mixers in the construction landscape. Dive into the intricate workings of these cutting-edge machines, redefining efficiency and precision in concrete mixing. Explore how volumetric mixers operate and why they’re reshaping the industry.

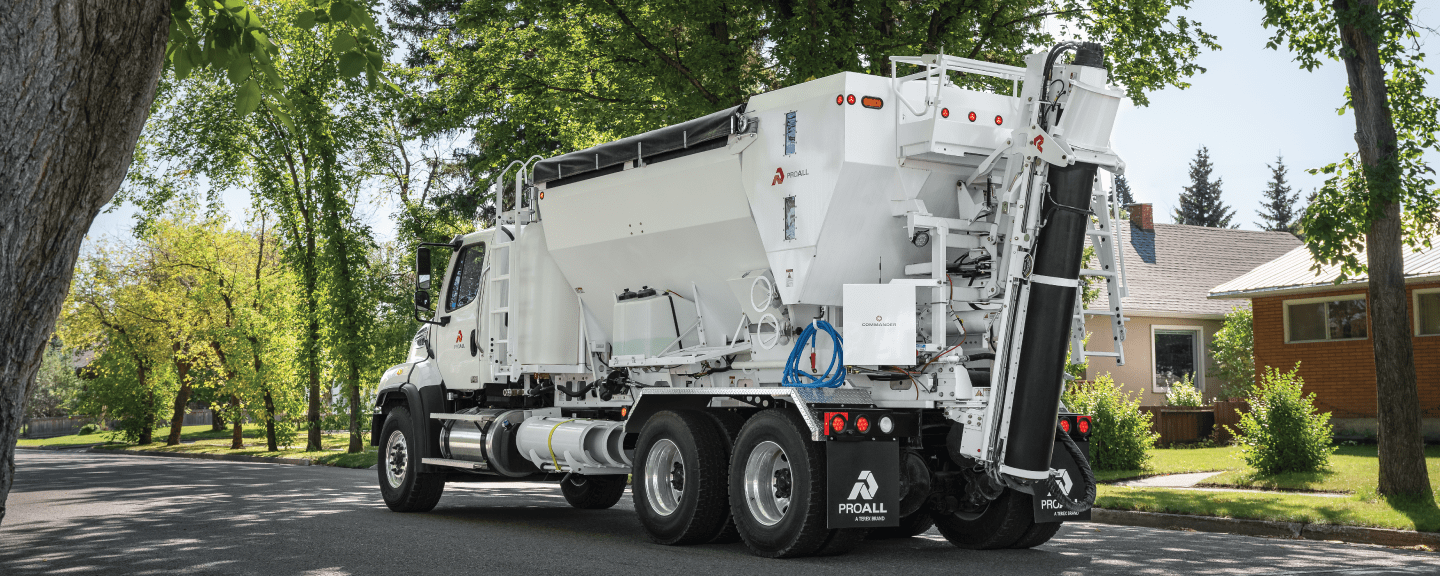

What is a Volumetric Mixer?

Unveiling the versatility of volumetric mixers, mobile concrete mixers, or volumetric concrete mixers. Learn how these specialized vehicles revolutionize on-site concrete production by blending cement, aggregates, water, and additives directly at the point of use. Experience the flexibility to adjust mix designs in real time to meet project specifics.

How Does a Volumetric Mixer Work?

Unlock the inner workings of volumetric mixers with our comprehensive breakdown:

- Ingredient Storage: Explore the multiple compartments tailored for cement, aggregates, water, and additives, ensuring seamless mixing customization.

- Proportional Mixing: Delve into the precision of the computerized control system, accurately dispensing ingredients into the mixing chamber based on designated mix proportions.

- Mixing Process: Witness the synchronized operation of augers and conveyor belts, guaranteeing uniform blending for consistent quality across each batch.

- On-Demand Delivery: Experience the convenience of controlled discharge rates, enabling precise delivery matching the pace of construction activities, minimizing waste, and optimizing efficiency.

Benefits of Volumetric Mixers:

Unlock the advantages driving the adoption of volumetric mixers:

- Customization: Maximize flexibility with complete control over mix designs tailored to project requirements for optimal results.

- Time and Cost Savings: Embrace streamlined construction processes, reducing transportation needs and minimizing waste for enhanced project economics.

- Quality Assurance: Ensure superior concrete quality with on-site mixing, mitigating risks of variation or contamination during transportation.

- Versatility: From minor repairs to large-scale projects, embrace the adaptability of volumetric mixers, accommodating diverse materials and mix designs.

Embrace the future of concrete mixing with volumetric mixers, poised to revolutionize construction practices. Seamlessly blending efficiency, precision, and versatility, these innovative machines pave the way for enhanced project outcomes. As the construction landscape evolves, volumetric mixers are indispensable tools, driving progress in the built environment.