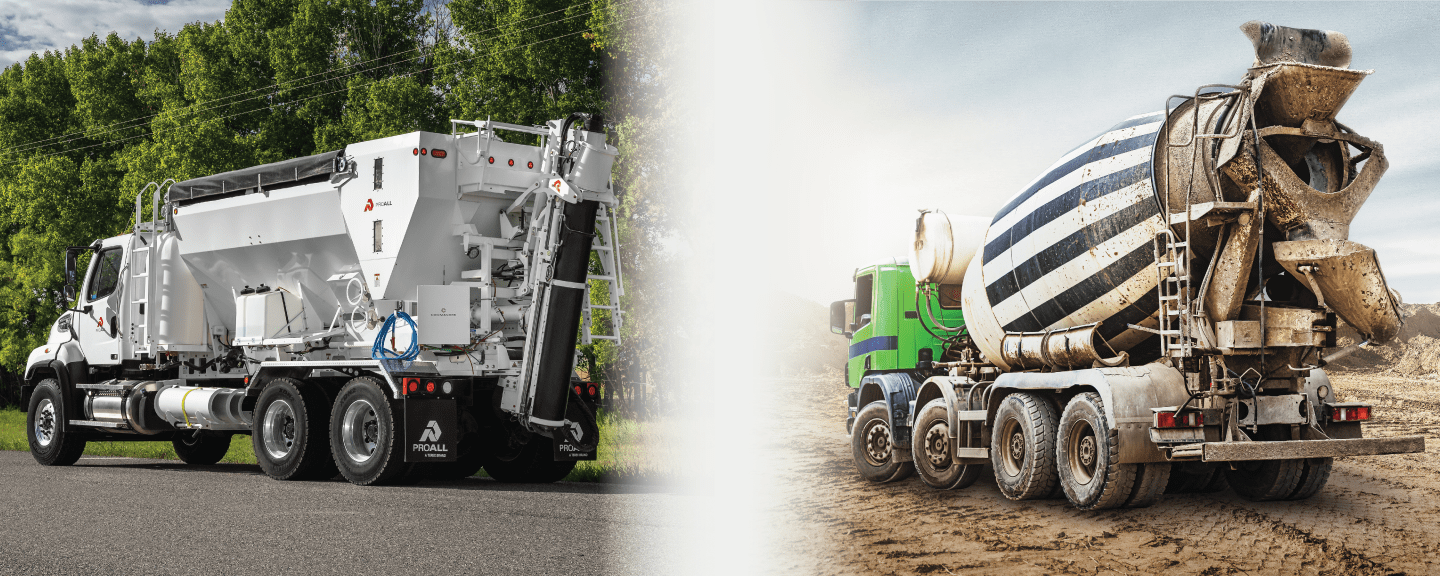

Ready Mixer vs. Volumetric Mixers: Choosing an On-Site Concrete Solution

Discover the distinctions between a ready mixer and volumetric mixer for on-site concrete production. Dive into the superior flexibility and efficiency offered by volumetric mixers. Explore the unique benefits of each option and identify which projects benefit most from their respective strengths.

Ready Mixer vs. Volumetric Mixers: Deciphering the Best Option

Ready Mixer:

Ready-mix concrete, typically manufactured in central batch plants, involves pre-mixing ingredients before transportation. While convenient, ready mix lacks the adaptability and customization of volumetric mixers.

Who Benefits from a Ready Mixer:

- Large-scale construction projects benefit from the consistent quality and high-volume production capabilities of ready-mix concrete, ideal for projects with uniform concrete requirements.

- Projects with limited on-site resources, such as labor or equipment for on-site mixing, find ready-mix concrete advantageous, as it streamlines the construction process and reduces the need for additional infrastructure.

Volumetric Mixer:

Volumetric mixers revolutionize on-site concrete production by blending materials directly at the job site. With separate compartments for ingredients, volumetric mixers provide precise control over mix designs, ensuring tailored solutions for every project need.

Who Benefits from a Volumetric Mixer:

- Small to medium-sized construction projects benefit from the flexibility and cost-effectiveness of volumetric mixers, particularly for projects with varying concrete requirements.

- Road construction projects require on-site adjustments and precise mix designs for pavement durability and performance.

- Remote construction sites have limited access to central batch plants, making volumetric mixers the optimal choice for on-demand concrete production.

Why Volumetric Mixers Stand Out:

- Customization: Empowering contractors with complete control over mix designs, volumetric mixers ensure tailored solutions for specific project requirements, enhancing overall quality.

- On-Demand Mixing: By mixing concrete directly at the job site, volumetric mixers minimize waste, reduce transportation costs, and optimize project efficiency.

- Real-Time Adjustments: Operators can instantly modify mix proportions to maintain consistency and quality, adapting seamlessly to changing project demands.

- Versatility: With the ability to handle diverse materials and mix designs, volumetric mixers are ideal for various construction projects, from small-scale repairs to large-scale developments.

Both options offer distinct advantages depending on project requirements when comparing ready mix and volumetric mixers. While a ready mixer excels in consistent quality and high-volume production for large-scale projects, volumetric mixers provide unparalleled flexibility and efficiency for smaller, more varied projects. Choose the option that best suits your project needs and experience the benefits of on-site concrete production.