WHAT IS RAPID SET CONCRETE?

WHAT IS RAPID-SET CONCRETE?

No two construction projects are the same, but in most cases, contractors work to tight deadlines and project schedules. Waiting several days for concrete to cure before progressing is not always the best option. Rapid-set concrete helps you meet tight deadlines without compromising on build strength and quality. The versatility of mobile concrete mixers makes the use of rapid-set concrete possible – in a readymix drum truck, the product would harden and be unusable (not to mention damage the machine).

COMPARING RAPID-SET AND TRADITIONAL CONCRETE

Any concrete mix starts with three basic ingredients: cement, water, and aggregates such as sand. Changing the proportions of those ingredients will change the characteristics of your mix. Creating rapid-set concrete means adding a higher proportion of cement than standard mixes.

For many applications, contractors will also add certain admixtures to reduce hydration time and accelerate the hardening process further. The goal is to create strong, versatile concrete whilst minimizing time spent on this part of the construction project. Standard, traditional concrete mixes tend to take up to 48 hours to dry. Rapid-set mixes can dry in as little as one hour, depending on the specifications of the mix.

Despite faster setting times, there is no need to compromise on build quality. Rapid-set mixes used by professional contractors are strong enough to be used in large structures and bridge projects.

They differ substantially from pre-mixed rapid-setting concrete available in DIY stores. That kind of concrete is better suited to small repairs and non-structural uses.

BENEFITS OF RAPID-SET CONCRETE

Rapid-set concrete has several advantages over more traditional mixes.

- Reduced Shrinkage And Quick Strength Gain

- Reduced Labor and Project Cost

- Reduced Downtime

- Better Use Of Mobile Mixers

REDUCED SHRINKAGE AND QUICK STRENGTH GAIN

Shrinkage is one of the main reasons that concrete projects fail. In any concrete project, shrinkage happens when the water in the mix evaporates as the cement hydrates. Depending on the degree of shrinkage and whether it leads to major cracks, contractors may need to set aside time to address the issue.

Putting joints in the concrete can mitigate crack formation, but rapid-set mixes avoid this problem from the start. They are designed to shrink three to four times less than traditional mixes. Because of the quick strength gain of rapid-set mixes, they also resist shrinking on a synergistic level. As a contractor, you are less dependent on joints and can generally complete a project more quickly.

REDUCED LABOR AND PROJECT COST

Apart from materials, labor is one of the biggest costs in any construction project. Rapid-set concrete can help you reduce your labor cost by up to 50%. This is a huge saving for any contractor and their clients. As a result, using faster-setting concrete helps you bid more competitively.

Rather than waiting several days to progress with a project, your team can continue almost straight away. Not only does this help meet deadlines, but it also makes it easier to manage crew schedules. If you are only contracted for the concrete part of a construction project, using rapid-set materials frees up your team faster and they are ready for the next challenge. From a business perspective, this allows you to complete more jobs with the same size of the workforce.

REDUCED DOWNTIME

Rapid-set mixes are an excellent option for contractors who are involved in major highway or bridge repairs. Having to close any major traffic artery means cars and trucks will back up on minor roads. Therefore, transportation departments generally require contractors to work as fast as possible.

Being able to set up a continuous flow pour with a volumetric concrete mixer and pouring rapid-setting mixes is the best solution to minimize the time it takes to complete a project.

In some cases, road closures and diversions are not an option. Instead, contractors need to work overnight as the traffic is generally lighter. Even with reflective protection equipment and powerful lights to illuminate work sites, overnight repairs are dangerous for the team on-site as well as cars driving through.

In these situations, rapid-set concrete helps complete the job quickly and keeps road users safe. Depending on the specifics of the mix, a typical rapid-set concrete can set within 20 minutes and may be ready for traffic within an hour or two.

Compare that to traditional mixes which may need to cure for anything between three and seven days. Traveling over the new surface or drilling holes to insert bolts before traditional concrete has reached sufficient strength, could cause the entire project to fail.

A GREAT USE OF MOBILE MIXERS

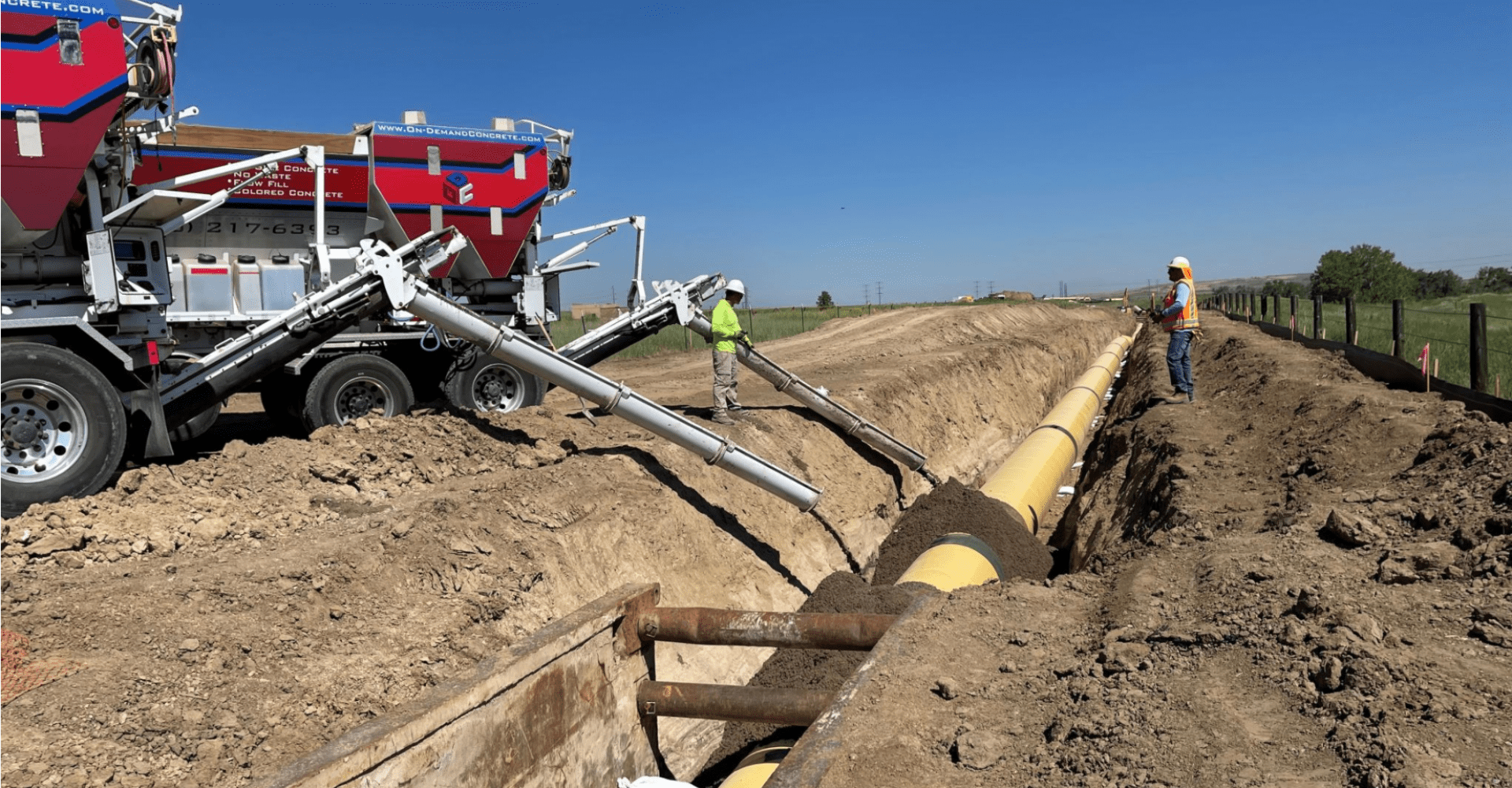

Rapid-setting concrete allows you to streamline construction projects and work more efficiently. Volumetric concrete mixers complement these materials perfectly. Being able to mix on-site means you are pouring concrete exactly when and where it is needed. Mobile mixers are the perfect equipment solution for rapid-set projects as they allow the mix to be produced on-demand, preventing the mix from hardening inside (as it would in a ready mix truck).

Rapid-set concrete mixes and volumetric mobile mixers are a perfect combination for contractors needing to work to tight deadlines. In challenging circumstances like overnight road or runway repairs (like the US military requires), this blend of equipment and material helps you increase safety for your team and road users. In addition, your clients benefit from streamlined project delivery without compromising on build quality. It is an unbeatable combination for countless construction projects.

Looking to introduce rapid-set concrete to your product offerings but don’t know where to start? Contact us today to speak with one of our experts!