THE CHALLENGE

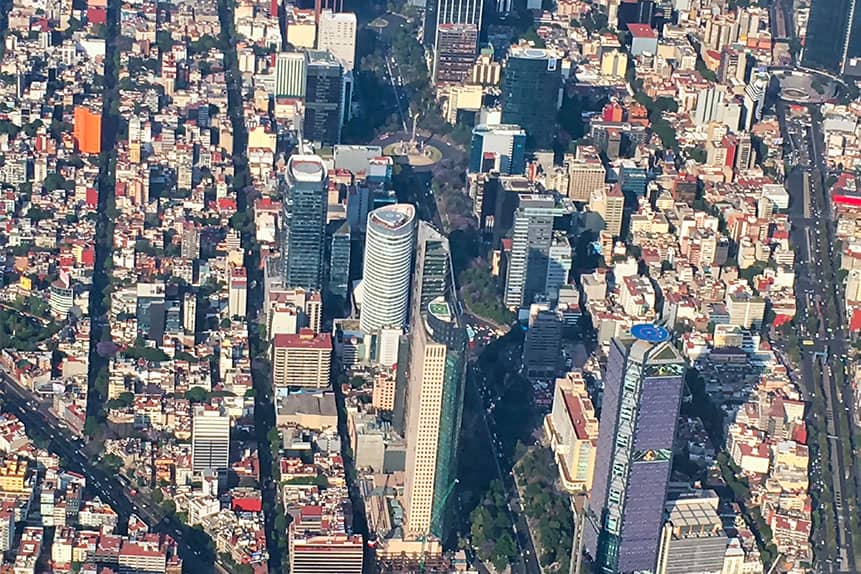

Yoram and Sholem Cimet faced two problems while building the Torre Glorieta office building in the heart of Mexico City. In order for their building to withstand the risk of earthquake and meet the strict building guidelines of the city, they needed to source a Class One concrete. This concrete has the highest dimensional weight and modulus of elasticity that can be obtained, ensuring it maintains flexibility. Sourcing concrete of such high specifications in the very center of Mexico City, the largest metropolitan area in the western hemisphere, was a massive challenge. They found that the travel time of the trucks from the plant to the building site made it impossible to obtain that elastic modulus, due to water or other additives being needed upon arrival. In the end, no supplier or contractor made offers on the job, as none could assure that concrete could be supplied within the city’s tight standards.

THE SOLUTION

A ProAll Mixer was the perfect solution to this two-sided problem. One ProAll Mixer allowed the crew to take total control of their delivery logistics and eliminated the possibility of a poor mix design by only mixing the concrete materials when needed, ensuring the elastic modulus levels are maintained. To ensure all specifications were being met, an on-site lab performed over 800 tests throughout the construction process, testing the concrete for elasticity, dimensional weight, and resistance. There wasn’t a single failed test.

STRICT BUILDING GUIDELINES

In the decades since the deadly 1985 earthquake, Mexico City has taken significant steps toward addressing earthquake risk. One area of focus has been the city’s buildings, with heightened structural resistance measures mandated in step with the latest advances in engineering. Zoning regulations, building codes, and laws focusing on new construction projects are very demanding and strictly enforced. Skyscrapers everywhere must be reinforced to withstand strong forces from high winds, but in quake zones, there are additional considerations. Engineers must design structures that can absorb the energy of the waves throughout the height of the building. Floors and walls can be constructed to transfer the shaking energy downward through the building and back to the ground. The joints between supportive parts of a building must be reinforced to tolerate being bent or misshapen by earthquake forces.

Passed On-Site Tests

Trips to Batch-Plant Avoided

The ProAll Volumetric Mixer is the only way we could achieve the adequate elastic modulus during the process without any problems. It gave us the peace of mind that we have a very well-built structure, even with the heightened risk of earthquake activity here

Sholem Cimet, Architect for Constructora Cimet

Contact Us

Today!

Whether you're new to volumetric mixers, need a quote, or a spare part - we're here to help.

Get In Touch